How Is Sheet Metal is Made

The first step is to melt the metal in a container called a crucible

When the metal is completely melted, it is poured out of the crucible and into a rectangular mold. The metal must be kept hot as it is poured into the mold so that it does not begin to harden outside of the mold.

When the metal has cooled completely, it is taken out of the mold. We now have a rectangular block of metal known as an ingot. The ingot is then dipped into a mixture of chemicals to be cleaned; a process known as pickling.

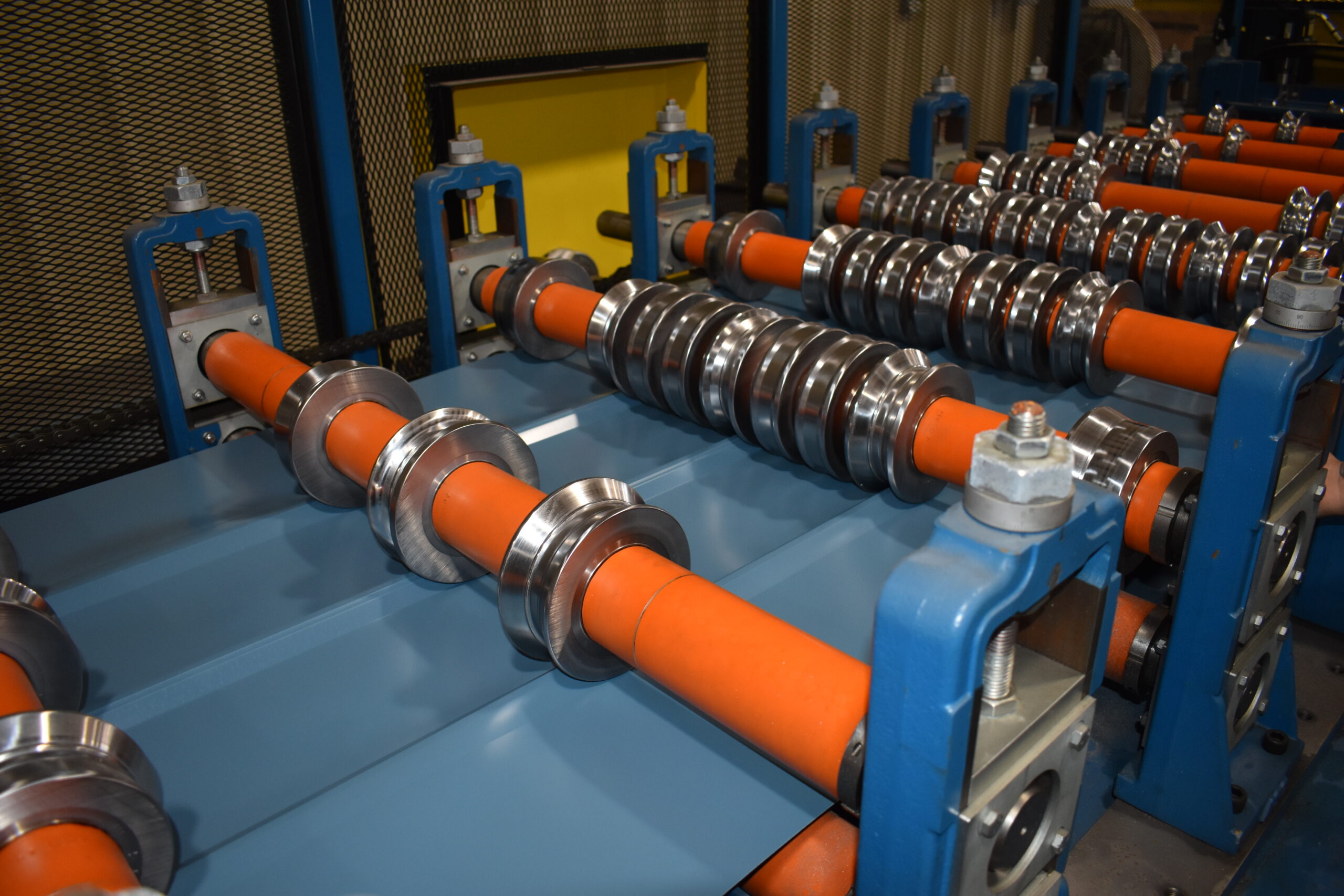

Rolling

Once the ingot has been cleaned, it is put through a press. The press consists of two large rollers that thin out the metal. The press rollers are then moved closer together and the metal is run through again. Ingots may have to be run through the press several times before they reach the desired thickness.

Annealing

As the ingot is run through the press the metal will become increasingly harder. It may be necessary to anneal the metal several times throughout the rolling process. Annealing the metal consists of heating it up and then pickling it again. During the annealing process the metal is only made warm-it is not melted again.

Shipping

After the metal reaches the desired thickness, it is either shipped flat or rolled into a coil. Finished sheet metal is anywhere from .05 millimeters to 15 centimeters thick.

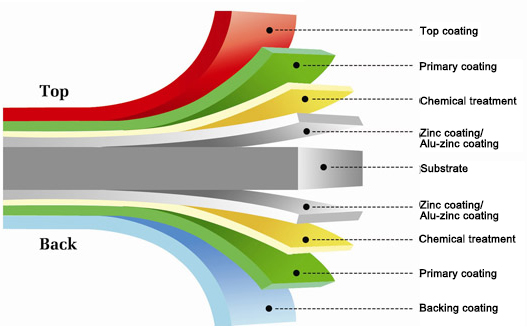

Painting is a process that involves as many as 9 layers of coating material.

The entire coil of metal which is usually 4,000 to 5,000 feet long and weighs as much as 10,000 pounds. The entire coil is sent through a process that first unrolls the coil of metal then several coats of primer and paint are applied, and sent through a dryer to dry, then re-rolled into a coil.

These Coils each can weigh as much as two cars. Each year we must anticipate how much of each color we will need, 6 months in advance, we place orders anticipating how much of each color we might sell, then cross our fingers.

Rollforming is the process of decoiling the sheet metal using a (you guessed it), “decoiler” and running the material through a series of tooling that each shape the metal a little at a time until the desired profile is completed, at that time the machine engages the flying shear to cut each piece to the right length. We use 3 of these machines that operate at about 115 feet per minute in order to process our normal weekly consumption of about 125,000 feet per week.